Investing today for our tomorrow

In the last few years Babbini Company has made a lot of investments to optimize its human resources, employing new staff to support the existing personnel in the light of the workload increase occurred in the last 4 years. Moreover it potentiated key departments of the company, such as the R&D Dpt, in order to improve reliability and performance focusing on the analysis of the feedback from customers. Several investments have been planned thanks to the results achieved by our research workgroups and after analysing and optimizing all welding processes involved in the spindles manufacturing in order to continuously assure the higher and higher quality standards of our product.

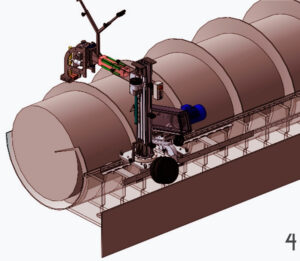

We focused on the purchasing of several automatic welding systems, of a new Numerically Controlled lathing machine with lathing/milling group and customization of software for planning and traceability. Moreover we developed our Service by employing more staff and by optimizing a new welding/grinding machine to rebuild the hard facing on worn out flights directly on site.

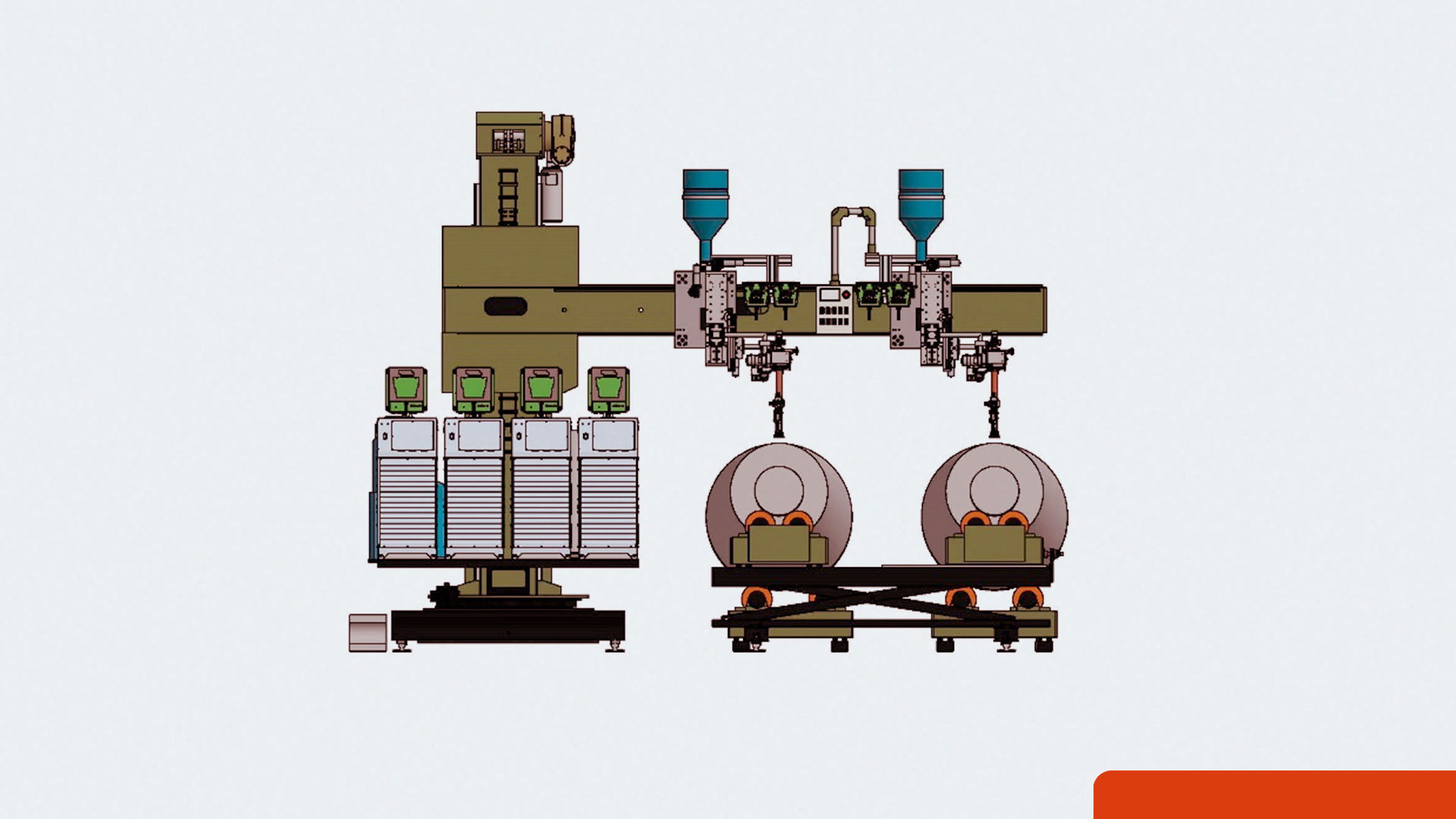

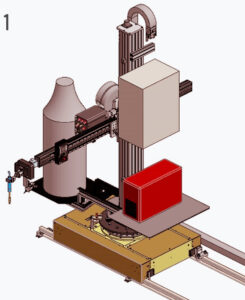

fig. 1 Automatic longitudinal and circumferential welding plant. Expected delivery: March 2017

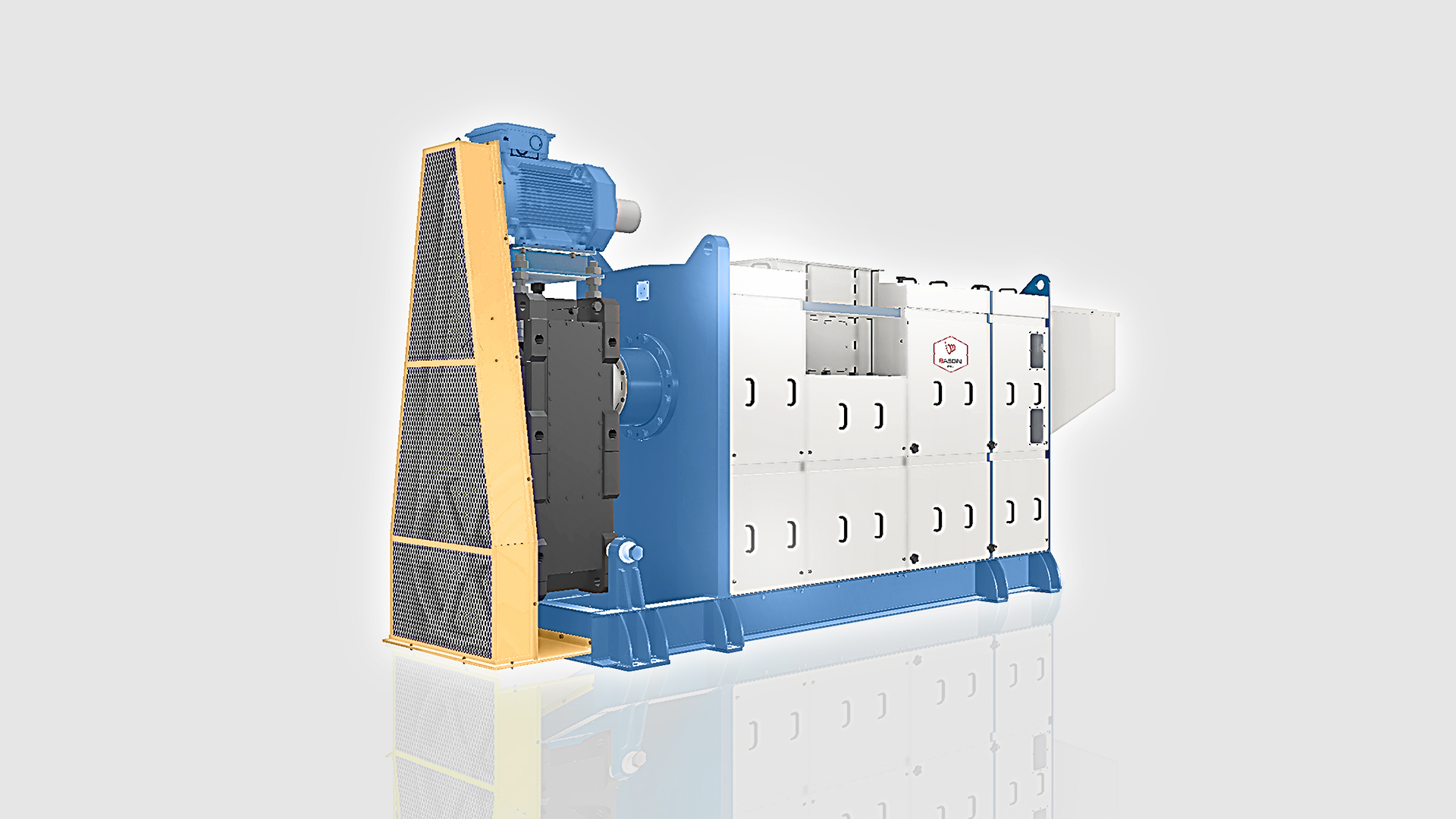

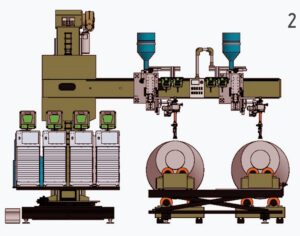

fig. 2 Submerged arc welding plant. Expected delivery: May 2017

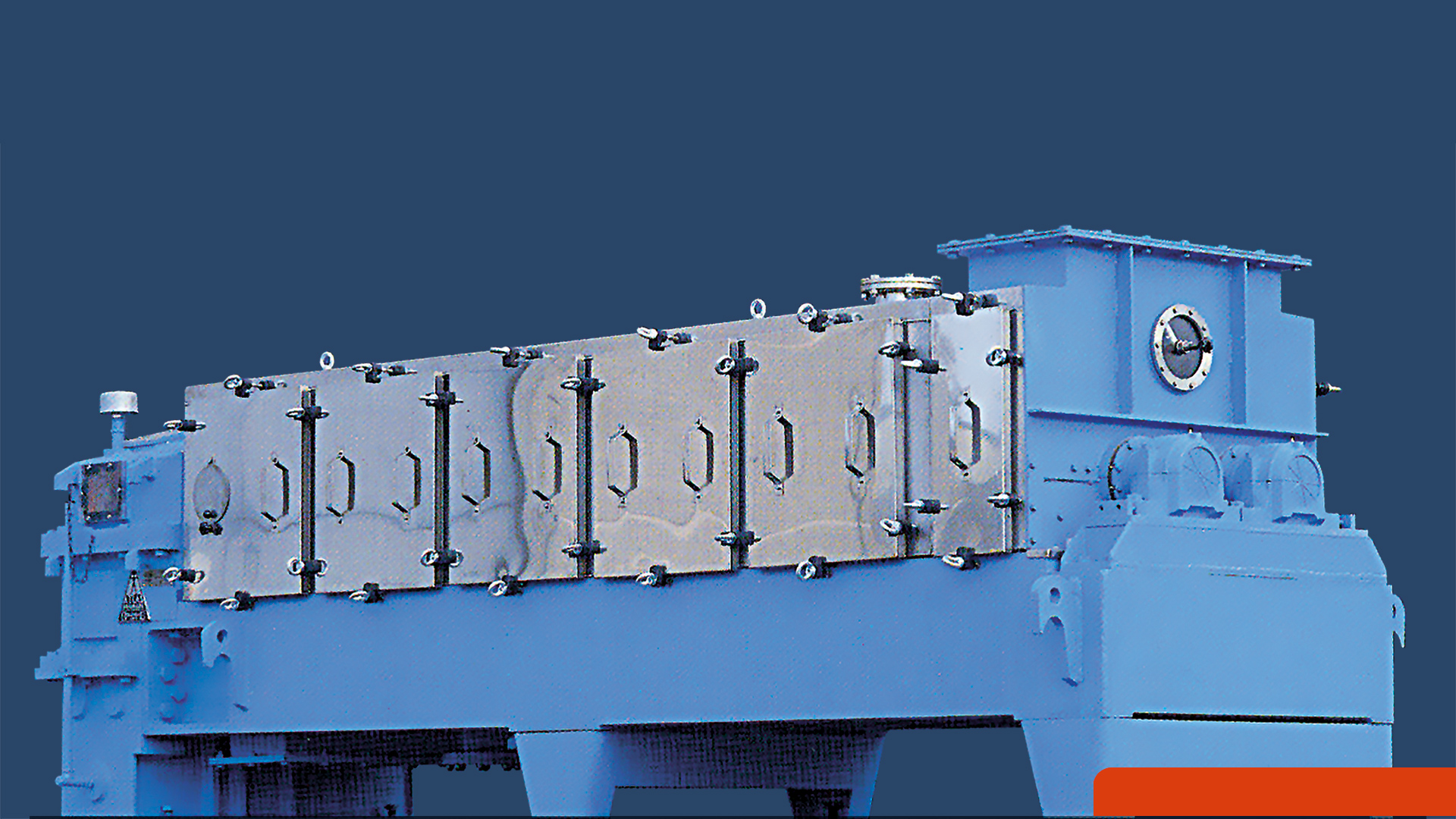

fig. 3 Numerically Controlled lathing machine with lathing and milling group. Lathing length 14m, diameter 2m, carrying capacity 40T

fig. 4 Plant for automatic welding and milling of the hard facing on the top of the flights with analogical management and control of final diameter. Plant to rebuild the hard facing on worn out flights directly on site.